Professional testing & evaluation of welded joints in metal, steel and plant construction

Non-destructive testing is one of the most important components of quality assurance in metal and steel construction.

Non-Destructive Testing (NDT) is an essential part of modern quality assurance in metal construction, steel construction and industrial plant engineering.

Our team supports companies, operators and clients in the welding of joints, components and structures. Safe, standard-compliant and efficient without damaging the components.

The combination of certified test methods (VT2 / PT2) and welding expertise (IWE/EWE) we offer more than just fault detection:

We deliver Technically sound, comprehensible and, if necessary, court-proof assessments, which are recognized in the international environment.

Our range of NDT (non-destructive testing) / NDT (non-destructive testing) services

Visual inspection - VT (ISO 9712 / ISO 17637)

The PT test enables the detection of the finest cracks and pores that are not visually visible.

We use both colored and fluorescent test equipment and document the results in accordance with standards.

- Weld seam geometry

- Surface defects

- Burn-in notches

- Dimensional accuracy

- Default

- Final contours and seam quality

to assess.

The valuation is based on DIN EN ISO 5817 / ISO 10042.

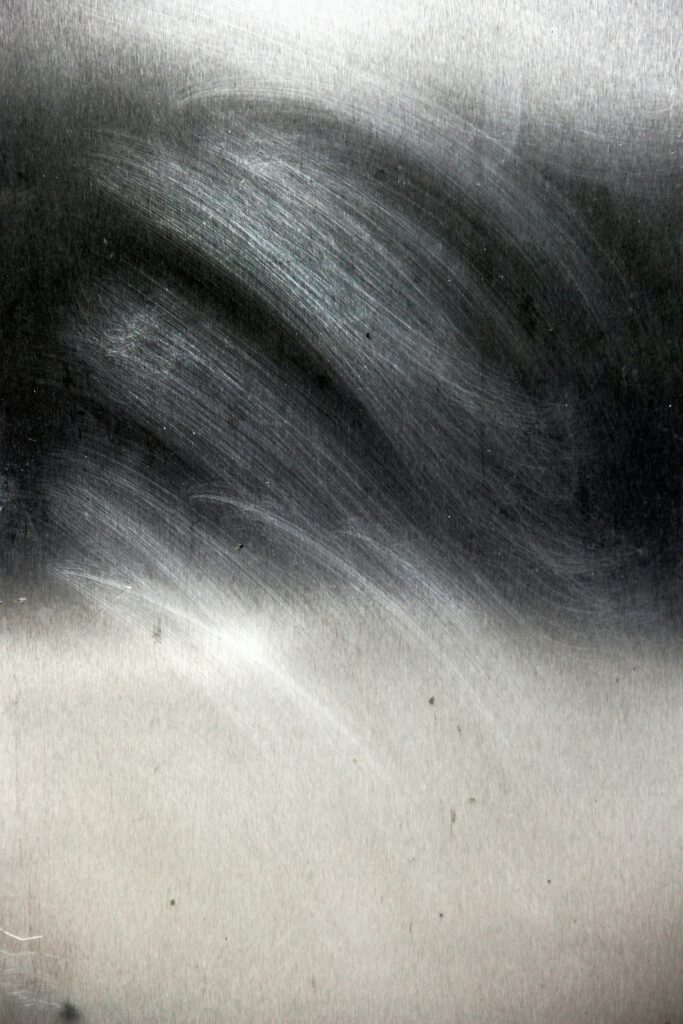

Penetrant testing - PT (ISO 9712 / ISO 3452)

The PT test enables the detection of the finest cracks and pores that are not visually visible.

We use both colored and fluorescent test equipment and document the results in accordance with standards.

Typical applications:

- Stainless steel and aluminum constructions

- Galvanized components

- Welded joints on beams, brackets, pipelines

- Cast and forged parts

All results are documented in accordance with standards.

Where non-destructive testing is used

Our team supports manufacturers, installation companies and operators in the field:

- Quality assurance according to EN 1090 / ISO 3834

- Acceptance tests in steel and metal construction

- Checking railings, stairs, facades

- Inspection of load-bearing components & junctions

- EMPB / initial sample documentation

- Production, assembly & final acceptance

NDT within the scope of expert opinions & damage analyses

As a publicly appointed expert, we combine NDT testing with expert appraisal. We inspect, assess and document damage to:

- Welded joints

- Beams & steel structures

- Components on industrial plants

- Staircase, balcony & railing constructions

- Pipeline construction (Piping)

- Containers & pressure components

- Mechanical engineering components

We deliver:

- Root cause analyses

- Classification according to standard

- Technical risk assessment

- court-proof documentation

Why our NDT services are in demand nationwide

✔️ Inspection + evaluation + recommendation

We not only deliver results - we also explain the technical background and provide specific recommendations for action.

✔️ ISO-certified: VT2 / PT2 according to DIN EN ISO 9712

Recognized in mechanical engineering, steel construction, plant engineering and industrial environments.

✔️ Expert competence

Valuation by a publicly appointed and sworn expert.

✔️ Standard-compliant test reports & photo documentation

Accepted by auditors, certification bodies, operators and inspection authorities.

✔️ Fast availability for small businesses and industry

Ideal for acceptance tests, EN 1090, ISO 3834, EMPB, production inspections and damage claims.

✔️ Even in safety-critical industries

Chemicals, energy systems, pressure equipment, steel structures, maritime technology.

Supra-regional NDT services - VT & PT according to ISO 9712 for Rhine-Main, Rhine-Neckar & nationwide

Non-destructive testing (NDT) is absolutely essential in many industries in order to be able to evaluate welded joints, components and structures reliably and in accordance with standards.

As many companies are unable to provide their own certified tester in accordance with DIN EN ISO 9712, we offer our VT2 and PT2 examinations nationwide flexible, at short notice and with a technically sound assessment by a publicly appointed expert.

Our area of operation covers the entire Rhine-Main and Rhine-Neckar region, in particular:

- Mannheim

- Ludwigshafen

- Frankfurt am Main

- Wiesbaden

- Mainz

- Darmstadt

- Heidelberg

- Karlsruhe

as well as nationwide assignments by arrangement.

Especially in the industrial environment - e.g. BASF, chemical parks, mechanical engineering, steel construction and plant engineering companies - our combination of NDT test + technical welding assessment particularly appreciated.

Suitable for metal construction, steel construction, industry & special sectors

Our NDT services (VT / PT) are frequently used in the following areas:

- Metal and steel construction

- Pipeline construction (piping / process technology)

- Mechanical and plant engineering

- Chemical industry / petrochemicals

- Tank, pressure equipment and apparatus engineering

- Hall construction, structural engineering, railings, stairs, balconies

- Stainless steel and aluminum processing

- Special components, series production, thin-walled welded constructions

- Offshore, tower and construction technology

The direct combination of VT2/PT2 according to ISO 9712 with IWE competence and expert assessment clients receive both a Technically correct NDT testing as well as a Technical assessment of the results - something that traditional inspection services do not offer in this form.

Case study

Zinc cracks after hot-dip galvanizing - causes, analysis and evaluation

Contact us

Do you need quality assurance during construction or support with EN 1090 audits?

E-Mail: info@metall-sv.de

Phone: 06131 / 89 39 500

Or use our Contact form.